- Home

- Equipments

- Tensile Strength Tester

- Hydraulic GSM Cutter

- Denier Count Wrap Reel

- Yarn Twist Tester

- Yarn Tension Meter

- Yarn Shore Hardnes Tester

- Tearing Strength Tester

- Button Pull Strength Test

- Bursting Strength Tester

- Sample Lab Dyeing Machin

- Color Matching Equipments

- Color Fastness Tester

- Abrasion cum Pilling Test

- Digital Thickness Gauge

- Crease Recovery Tester

- Stiffness Tester

- Repellent Penetration

- Knowledge

- Testing Instruments Guide

- Support

Yarn Tension Meter, Digital Tension Meter, Analog Tension Meter, Dial Type Tension Meter, Schmidt Germany Tension Meter, Tension Meter for Knitting Weaving Winding Twisting Warping Beaming Sizing Texturing Industry

Digital Yarn Tension Meter

Yarn Tension Meter, Digital Tension Meter, Analog Tension Meter, Dial Type Tension Meter, Schmidt Germany Tension Meter, Tension Meter for Knitting Weaving Winding Twisting Warping Beaming Sizing Texturing Industry is used to determine tension of moving yarn during fabric manufacturing process in textile industry.

Better than Analogue Yarn Tension Meter and it is used to determine tension of moving yarn in knitting, weaving, winding, twisting, warping, beaming, sizing, machines. Available Digital, Accurate, Dial type.

B-Tex Engineering provides international quality Digital Yarn Tension Meter at affordable price.It is very essential to judge the tension in the moving yarn. This instrument determines load during processing of yarn while spinning and winding, followed again during warping, it is also used during weft winding. Yarn being very sensitive to tension should be checked by means of tension meter. The instrument is very sensitive, give reproducible and stable readings, if the measuring conditions are repeated; therefore it is advisable to select proper range of tension meter.

There are two kind of Tension Meters are available with different kind of grips.

Dial type tension meters are good for overall testing but if you want to check machine’s hidden tension as value fluctuation then digital one are the best. Spring base Dial Tension Meter can’t give hidden vibration readings of 0.1 gm accuracy with 300 gm capacity range at this low price.

Digital Tension Meters are highly sensitive and can give more accurate results with more practice, it will shows hidden vibrations as values also.

Features of Digital Yarn Tension Meter:

This instrument is manufactured in an easy to handle design, size and weight.

Gives accurate results.

Specifications of Digital Yarn Tension Meter:

Size of the Instrument: 182 mm x 36 mm x 26 mmLoad Capacity: 300 gm., 0.1gm Accuracy.Weight : 112 gm.Battery: LR 44, Button cell

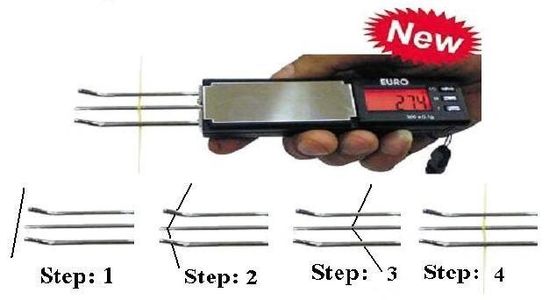

How Digital Yarn Tension Meter works?

Press I/O button to start tension metre and wait till 0.0 value is displayed.

Hold the sensor in the direction of the path of yarn.

Then press T (Tare) button and wait for 0.0 value is on screen.

Pick up yarn with the help of sensor and make 120-160 degree angle of yarn in the middle of two bands.

Now slide yarn in the center of bands and sensor.

Then maintain the passage of yarn by pressing instrument back side and get actual reflection of load.

The Digital Yarn Tension Meter confirms with the international standards and comes under warranty. All this help provide customer satisfaction that promotes long term customer relationship which is our ultimate objective at B-Tex Engineering.

Minimum 10 years part availability assurance from the date of Invoice.

Digital Yarn Tension Meter Raller Type

Digital Yarn Tension Meter (Roller Type Blue) is used to determine the online tension of moving yarn in knitting & weaving machines, also used by texturising units, TFO (Two For One) Twisting units, Sizing Units, Draw Warping Units, and POY units.

It is very essential to judge the tension in the moving yarn. This instrument determines load during processing of yarn while spinning and winding, followed again during warping, it is also used during weft winding. Yarn being very sensitive to tension should be checked by means of tension meter. The instrument is very sensitive, give reproducible and stable readings, if the measuring conditions are repeated; therefore it is advisable to select proper range of tension meter.Digital Yarn Tension Meter (Roller Type) is widely used by yarn manufacturing companies, like texturising units, TFO (Two For One) Twisting units, Sizing Units, Draw Warping Units, and POY units during yarn/fiber manufacturing process to cheeck the online tension of moving yarns.

Features of Digital Yarn Tension Meter Roller :

- This instrument is manufactured in an easy to handle design, size and weight.

- Gives accurate results.

- Range 0 gm. - 300gm

- 0.1 gm. Deviation

- 3 Button cells.

- Neck hanging facility.

Specifications of Digital Yarn Tension Meter Roller :

Size of the Instrument: 182 MM X 36 mm x 26 mm

Load Capacity: 300 gm., 0.1gm Accuracy, and With Max Hold Facility option.

Weight: 180 gm.

Battery: LR 44, Button cell

How to Digital Yarn Tension Meter Roller works?

- Press I/O button to start tension metre and wait till 0.0 display value.

- Press the M (Mode) button to select weight in gm., will display g /With Max Hold Facility option.

- Hold the sensor in the direction of the path of yarn.

- Then press T (Tare) button and wait for 0.0 values on screen.

- Take yarn in the path of three rallers by using knob behind the unit.

- Then maintain the passage of yarn by pressing instrument back side and get actual reflection of load.

- During checking procedure can use mode / M buttons to see last changed max value.

The Digital Yarn Tension Meter (Roller Type Blue)confirms with the international standards and comes under warranty. All this help provide customer satisfaction that promotes long term customer relationship which is our ultimate objective at B-Tex Engineering.

Minimum 10 years part availability assurance from the date of Invoice.

Digital Yarn Tension Meter Ceramic Guided

Digital Yarn Tension Meter Ceramic Guided, popularly known as Yarn Tension Meter is used to determine tension of moving yarn in knitting & weaving machines.

B-Tex Engineering provides international quality Digital Yarn Tension Meter at affordable price.It is very essential to judge the tension in the moving yarn. This instrument determines load during processing of yarn while spinning and winding, followed again during warping, it is also used during weft winding. Yarn being very sensitive to tension should be checked by means of tension meter. The instrument is very sensitive, give reproducible and stable readings, if the measuring conditions are repeated; therefore it is advisable to select proper range of tension meter.

Features of Digital Yarn Tension Meter Ceramic Guided:

- This instrument is manufactured in an easy to handle design, size and weight.

- Gives accurate results.

Specifications of Digital Yarn Tension Meter Ceramic Guided:

Size of the Instrument: 182 mm x 36 mm x 26 mmLoad Capacity: 300 gm., 0.1gm Accuracy.Weight: 112 gm.Battery: LR 44, Button cell

How Digital Yarn Tension Meter Ceramic Guided works?

- Press I/O button to start tension metre and wait till 0.0 value is displayed.

- Hold the sensor in the direction of the path of yarn.

- Then press T (Tare) button and wait for 0.0 value is on screen.

- Pick up yarn with the help of sensor and make 120-160 degree angle of yarn in the middle of two bands.

- Now slide yarn in the center of bands and sensor.

- Then maintain the passage of yarn by pressing instrument back side and get actual reflection of load.

The Digital Yarn Tension Meter Ceramic Guided confirms with the international standards and comes under warranty. All this help provide customer satisfaction that promotes long term customer relationship which is our ultimate objective at B-Tex Engineering.

Minimum 10 years part availability assurance from the date of Invoice.