- Home

- Equipments

- Tensile Strength Tester

- Hydraulic GSM Cutter

- Denier Count Wrap Reel

- Yarn Twist Tester

- Yarn Tension Meter

- Yarn Shore Hardnes Tester

- Tearing Strength Tester

- Button Pull Strength Test

- Bursting Strength Tester

- Sample Lab Dyeing Machin

- Color Matching Equipments

- Color Fastness Tester

- Abrasion cum Pilling Test

- Digital Thickness Gauge

- Crease Recovery Tester

- Stiffness Tester

- Repellent Penetration

- Knowledge

- Testing Instruments Guide

- Support

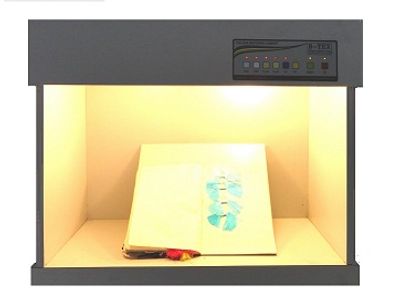

Color Matching Equipment, Textile Color Reader, Color Meter, Computerized Color Reader, Color Matching Cabinet, Yarn Fabric Textile Color Reader, Color Meter

Color Matching Equipment, Color Matching Cabinet, Yarn Fabric Dyeing

Color Matching Cabinet measures the color difference between two samples.

B-Tex Engineering provides you with high reliable and accurate Colour Matching Cabinet.Color looks different under different lighting condition. When one uses a Color Matching Cabinet it helps in marking the difference. Color Viewing Cabinets is equipped with most accurate light cabinet for visual evaluation of fabrics, garment, cloth, textiles, and leathers and so on. It checks matching under a standard light source in a closed environment to minimize the interference of external lights.

Color Matching Cabinet booth is used for visual assessment of color under 6 standard lights and comes with doors. Color Matching Cabinet, Light Box, is suitable for yarn, fabric dyeing plant, and garment manufacturer and exporters. Suitable for staining, change in color test by using grey scales during color fastness test.

Video Link: https://youtu.be/_XmoDuvhwBI

Features of Color Matching Cabinet :

Cabinet is made of Teakwood, Ply Board & Sun mica, with strict adherence to international standards.

Supplied with major tube lights & bulbs for quick and accurate color assessment.

Fitted with Electronic/ballasts for Instant start & power saving to safeguard the expensive & sensitive tube lights & bulbs

No warm-up; No flick; No heat emission; Elapsed Time displaying of each light source.

Energy saving; Efficient illumination.

Compact; High quality with low price.

Button Switches

Specifications of Color Matching Cabinet :

Overall Dimensions of the Instrument: 710±10 (L) x 414±10 (W) x 628±10 (H) mm

Overall Dimensions of the Viewing Cavity: 685±10 (L) x 408±10 (W) x 380±10 (H) mm

Net Weight of the Instrument: 25.480 Kg.

LIGHT SOURCES of Color Matching Cabinet :

Artificial Daylight Fluorescent Lamps (D-65): 01 Nos. (18 W)

Tungsten Filament Lamps : 04 Nos. (40 W)

Cool White Fluorescent Lamp (CWF): 01 No. (18 W)

Triphosphor Fluorescent Lamp (TL-84): 01 No. (18 W)

Ultra-Violet Black Lamp: 01 No. (8 W)

Warm White: 01 No. (18 W)

Color Matching Cabinet Confirms with following international standards:ISO 3664, BS 950, ASTM D 1729, DIN 6173

How Color Matching Cabinet works?

The equipment offers a wide viewing area equipped with multiple light sources or lamps to detect the phenomenon of Metamerism, where samples appear to match under one light source but is distinctly different under another. In order to reach the final approval the fabric has to go through various light sources which include: artificial daylight, cool white light, tungsten filament light, ultra violet black light, triphosphor fluorescent light.

The sample to be tested and the original sample are to be kept in the viewing cavity.

After switching on the D-65 Light closely check the original specimen and the specimen to be tested.

When the match is satisfactory, the specimen is to be tested under CWF Light and TFL Lamps.

Now the test is carried out under U.V.B Light, it is necessary to ascertain if both samples react equally to Ultra Violet radiation.

Then the final test is carried out under TL-84 Philips Triphosphor Fluorescent lamp tube light is carried to ascertain if the colors are acceptable at the ‘Point of Sale’.

All these help in judging the color differences accurately, by comparing the samples in different conditions. When the match of both samples holds well under all the lights, it means that the Dyeing, Printing and the coloring of the fabric or yarn is as per the requirement.

The Color Matching Cabinet confirms with the international standards and comes under warranty. All this help provide customer satisfaction that promotes long term customer relationship which is our ultimate objective at B-Tex Engineering.

Minimum 10 years part availability assurance from the date of Invoice.

Color Matching Equipment, Textile Color Reader, Color Meter, Computerized Color Reader, Yarn Fabric Textile, Color Reader, Color Meter

Color Matching Equipment, Computerized Color Reader, Yarn Fabric Dyeing, Textile Color Reader

Digital Color Reader measures the color difference between two samples.

B-Tex Engineering provides you with high reliable and accurate Digital Color Reader.

Color looks different under different lighting condition. When one uses a Digital Color Reader it helps in marking the difference.

Digital Color Reader is suitable for yarn, fabric dyeing plant, and garment manufacturer and exporters. Suitable for staining, change in color test by using grey scales during color fastness test.

Features of Digital Color Reader:

●Ultra stable performance

●Display precision 0.01

●Repeatability precision AE's standard deviation 0.1

●Enhance the measure accuracy through white and black calibration

Specifications of Digital Color Reader:

● Human engineering design

● Large data storage space

● Multiple modes of color values

● PC software and data control

● USB for data transmission

● Provides accurate measuring time settings

● Can manually set up L*a*b* value for standard samples

● Suitable for a company's internal and external color evaluation and data control

Digital Color Reader Confirms with following international standards: ISO 3664, BS 950, ASTM D 1729, DIN 6173